Fully recycled paper packaging for peanuts, made with concern for the environment and reducing the carbon footprint.

The paper substrate has been treated on the inside of the packaging with barrier coatings (against water, fat, water vapour, oxygen and with heat-seal properties) to achieve an airtight and fully protected product inside.

The printing was done with FlexiEco inks – a series of water-based inks made from renewable raw materials.

The printing plates used to print the paper are Carbon Neutral certified and made by Asahi Kasei using AWP™-DEW water-based technology, which has a lower environmental impact.

The sealing temperature of the packaging (approximately 150 degrees Celsius) allowed the packaging to be sealed and the product to be fully protected.

Paper packaging has the environmental advantage of lowering the carbon footprint of the printing process compared to conventionally produced packaging, i.e. using traditional film/plastic substrates, alcohol-based inks and photopolymer plates washed with solvent.

The use of Carbon Neutral certified inks and photopolymer plates in the production of our inks has enabled us to reduce the carbon footprint of our packaging compared to conventional packaging by 41%.

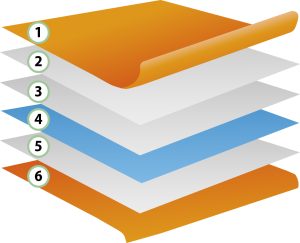

Packaging scheme /beginning with outer shell/:

- FlexiLack FX Barrier WOG 08 – barrier coating against water, grease and water vapor

- FlexiEco – waterborne inks based on renewable raw material

- Paper substrate (white)

- FlexiLack FX Barrier WO 03 FC – barrier coating against water and grease

- FlexiLack FX Barrier GA 08 FC – barrier coating against oxygen

- FlexiLack FX Barrier WO 07 FC – barrier coating against water and grease with heat-sealable properties

Benefits of packaging:

- elimination of lamination of paper substrate with PE foil

- enhanced recyclability of packaging

- reducing the negative impact on the environment

- water-based technology of inks and coatings

- broad functionality of barrier system – barrier to water, grease, oxygen and water vapor

- combination of barrier and heat-seal properties of the internal coating

Nowadays, packaging is the subject of intense public debates due to the growing share of packaging in the municipal waste stream. The ever-increasing amount of waste from various packaging materials such as plastic, paper, glass, etc. creates many environmental challenges. The lifespan of packaging is becoming shorter due to the dynamics of rotation of graphic patterns or shortening of packaging design series, therefore, after the packaging is used up, it becomes waste, ending up in a waste recycling plant or landfill.

The aim of creating a fully paper packaging for peanuts was to provide the market with packaging that can be quickly and easily recycled or neutralized through waste composting processes, becoming a reservoir of nutrients and organic matter in the soil.

Thanks to the components used; uncoated paper, coatings and paints made from materials derived from renewable raw materials and printing made using Carbon Neutral certified photopolymer plates, we have achieved undeniable success in reducing the carbon footprint of packaging by 41% compared to packaging made from traditional raw materials. Moreover, based on our experience and knowledge, we decided to calculate the impact of packaging not only on the atmosphere, but also on the pedosphere, hydrosphere and biosphere. Having empirical data, we can confirm that paper packaging for peanuts, compared to packaging prepared in a conventional way, is characterized by a lower toxicity index for humans by 55%, the impact of toxicity on the marine environment has been reduced by almost 35%, and the ecotoxicity of freshwater by 49%. However, the result of reducing the impact on ecotoxicity is spectacular, because the reduction in this aspect reaches almost 73%.

Paper packaging is one of the most environmentally friendly, its biodegradability is at a high level, and in biological decomposition processes, among others: paper (cellulose) supplies the natural environment with nutrients¹. Moreover, paper packaging is a response to the constantly increasing pollution of inland, sea and ocean waters with plastics and microplastics. The process of dissolving paper packaging in the aquatic environment is much faster than the biodegradation of plastics, so even if the paper packaging ends up in water, it will be dissolved quickly and easily². Chespa advocates and promotes environmentally friendly packaging as a solution to the ever-growing waste stream, especially plastic waste.